TOOLING DEVELOPMENT

Key Benefits

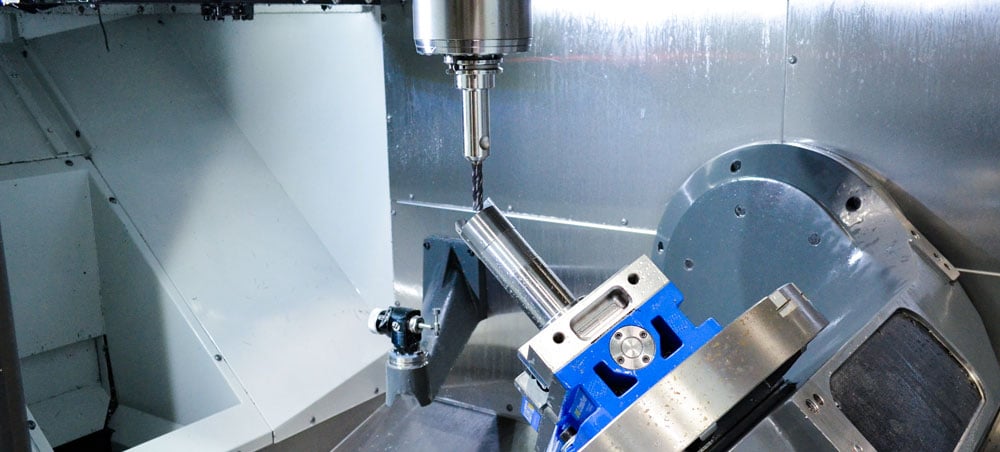

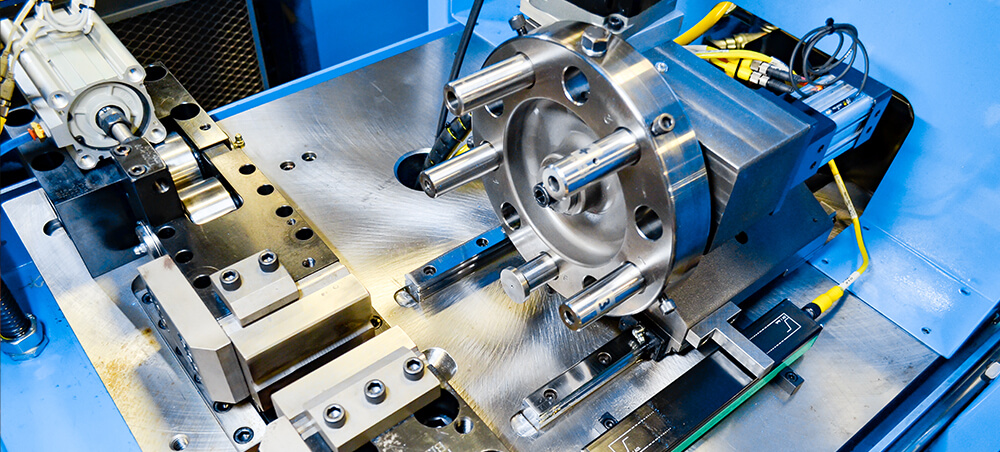

In-house CNC machining facility

Dedicated end forming machines for tooling tryout with equivalent models for every machine

572 years combined in-house tooling experience

Completed Design Package Includes:

Tooling component prints

Set-up information

Coating recommendations

Lubricant recommendations

Additional Tooling Development Services

We offer short-run tube end forming and end finishing using our own dedicated development machines. This service is ideal when it is more economical for our customers to employ our services in the initial stages of developing a tube end form fabrication for their own production process.

Additionally, we offer: