APPLICATIONS AND TECHNOLOGIES

Automation Solutions for Any Business Challenge

Wauseon Machine’s automation experience includes deep expertise in a wide range of applications and technologies, including assembly, pick/pack/pal, material logistics, and more. To learn more about our extensive experience in automation solutions and how we can help your organization, contact us today.

Assembly

Precision and flexibility are important in an assembly application. Systems designed and integrated by Wauseon Machine provide both. Automating your assembly process achieves many benefits, including repeatability tolerances otherwise unachievable with a human operator.

At Wauseon Machine, our vertical integration capabilities and deep expertise in assembly technology make us an ideal automation solutions partner for manufacturing organizations throughout their automation journey.

Palletizing (Pick/Pack/Pal)

From depalletizing water jugs and engine blocks to palletizing cases and bags, we have experience handling an array of products. Whether your goal is to increase output, reduce labor, or achieve cycle time reduction, an automated palletizing system from Wauseon Machine increases efficiency while providing a safer environment.

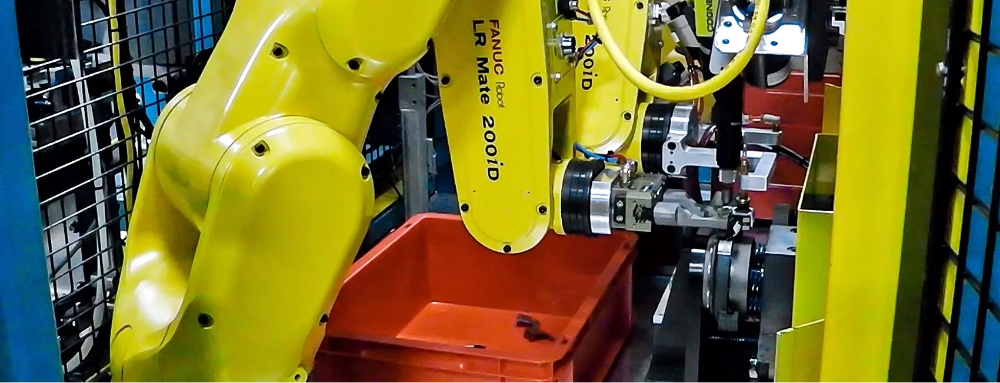

Dispensing

Wauseon Machine designs and integrates automated dispensing solutions that leverage various technologies, including Cartesian robots, SCARA robots, and 6-axis robots. Our dispensing solutions range from simple to complex and cover a wide range of materials.

Our solutions can range from a very simple pressure pot dispense cell to a closed-loop fluid monitoring system with vision to inspect bead quality. Additionally, we can integrate peripheral equipment into your system. Examples include:

- Vision systems to inspect dispense beads

- Closed-loop fluid monitoring systems

- Dual pump systems with automatic change over

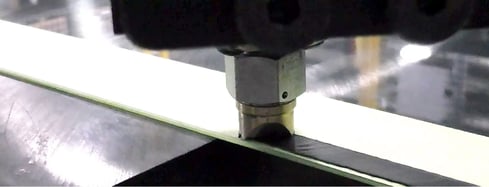

Inspection and Testing

No matter what our customers are making, we’re testing and verifying it. Whether through a standalone test machine or through an integrated solution as part of a cell or station, inspection and testing is a critical service we provide. Inspection and testing services include:

- Ensuring correct assembly, presence, and orientation

- Camera inspection

- Feature/part verification

- Leak testing

- Electrical testing

- Force over distance

Material Handling

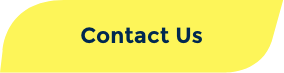

Flexible automation, such as an industrial robot, is ideal for material handling applications, and incorporating an industrial robotic arm into your manufacturing process provides numerous benefits. Reliability, safety, quality, productivity, and efficiency improvements are among the several reasons our customers turn to automated solutions in manufacturing.

Material handling solutions that we design and build include ancillary equipment that must work together seamlessly with a robot. This includes conveyor systems, part tracking technologies, labeling/marking, and other peripheral equipment. Technologies we also integrate include 2D and 3D vision, force sensing, and parts feeding to ensure the ultimate flexibility.

Machine Tending

Machine tending is the process of loading parts in and out of a machine. Integrating an industrial robot into your process is a great alternative to machine tending by a human operator. Our 20+ years of experience of building machine tending solutions has contributed to our ability to maximize efficiency of your system by analyzing parts accumulation between stations, part traceability, automated reject part strategy, and error recovery.

Material Logistics

Material logistics transforms operations by improving efficiency and connecting processes with AMRs/Autonomous Mobile Robots and often utilizing fleet management with navigation software technology.

This technology also increases the ability to transfer goods and reduce storage times while managing inventory traffic automatically and potentially autonomously.