Scalable. Adaptable. Modular.

Precision Machine Tending

The Kawasaki CL105 robot, front-mounted on a Wauseon Machine 1004EL End Former, delivers a fully automated machine tending solution. Featuring a T20 Magswitch Magnetic Gripper, automation-ready endformer, HMI tube stop adjustments, and advanced safety features, it ensures efficient and secure operation.

Adaptive Robotic Gear Assembly

Experience precision and efficiency with the Force Control Planetary Gear Assembly Cell, powered by the KUKA Agilus KR10R900-2 robot. Featuring Robot Sensor Interface (RSI) for real-time responsiveness, this system offers easy setup, quick adjustments, and real-time graphing for seamless performance monitoring

High Speed Vision Tracking

Achieve compact and efficient automation with a Circular Tracking System featuring FANUC iRVision, the R-30iB Compact Plus controller, and the SCARA SR-3iA robot. Designed for flexible automation, it’s ideal for high-speed, small part, pick-and-place applications.

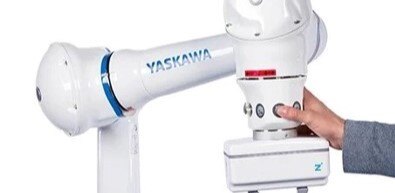

Industrial CoBot Robot Palletizing

Built for tough environments, the IP67-rated YASKAWA HC30PL XP Collaborative Robot pairs with the ultra-compact YRC1000micro controller for industrial-grade performance. With hand-guided teaching and on-screen 3D robot simulation, it offers intuitive programming and reliable, collaborative automation.

Collaborative Machine Tending

The ABB OmniVance Machine Tending Cell with the GoFa 12/1.27 collaborative robot offers a reliable and flexible solution for high-mix, low-volume production. Its open design ensures easy access, making it ideal for dynamic manufacturing environments.

Precision Pick-and-Place

This demonstration utilizes an ABB collaborative robot integrated with Coval’s advanced carbon fiber vacuum gripper for a precise pick-and-place operation. The robot transfers the component to IAI’s variable two-position

electric cylinders, which accurately position it for marking using the latest TechnoMark Tempo electric dot peen system.

Modular Robotic Assembly

This lightweight and portable solution features the YASKAWA HC10DTP Robot with the YRC1000micro controller and SCHUNK CRB50 tool changer. Designed with integrated smart features, this system offers scalable automation and plug-and-play end-of-arm tooling for fast, flexible deployment